Today, pharma companies are looking for innovative solutions to adapt to the volatile market demand. Despite fast technological progress, pharma businesses still face a number of problems in drug and batch manufacturing. For instance, in order to exclude human-made errors, Visual Inspection during manufacturing and packaging of batches should be performed.

This naturally increases the cost of labor and still leaves space for possible defects and flaws. Yet there is a solution to these typical issues in drugs and batch manufacturing, and this solution is AI (Artificial Intelligence).

Artificial Intelligence is a generic term for a set of technologies. In the case of the challenges described above, we will speak about two technologies: Machine Learning and Computer Vision. If we are talking about the most relevant and effective AI for pharma, then it is the most relevant choice.

Machine Learning for the pharma industry is the possibility to approximate, analyze, cluster, and classify a huge amount of data and solve complex problems within a short period of time offering smart solutions.

Computer Vision in the pharma industry is the unique chance to categorize an incredible amount of images or videos for object detection and tracking. The object can be cracked on the pill or poorly printed word on the batch. Computer Vision will guarantee 100% accuracy and instant detection compared to visual detection performed by employees.

AI for Pharma Use Cases: Defects Identification in Packaging

AI technologies can be effectively used to enhance the production of drugs on the stage of packaging. Machine Learning + Computer Vision for defect identification on the production line and during packaging. Using these technologies, it is possible to:

- Decrease time consumption during the packaging stage up to 14%;

- Identify defects of packaging (texture, shape, size, bad packing, etc.) on the production line and exclude them from production instantly;

- Significantly reduce labour cost and labour interaction.

Technologies Used for This Case

- CNN (convolutional neural network) approach for identification of sealing defects, medicine lackness in blisters, packaging defects, and batch defects;

- CV (computer vision) approach and customized CNNs may identify defects at any stage and require the development of the CNN that, with adjustments (training and setting of hyperparameters), may be used for most tasks. At some point, there might be a need to develop a unique CNN for the particular task.

Tech Stack: TensorFlow, OpenCV, etc.

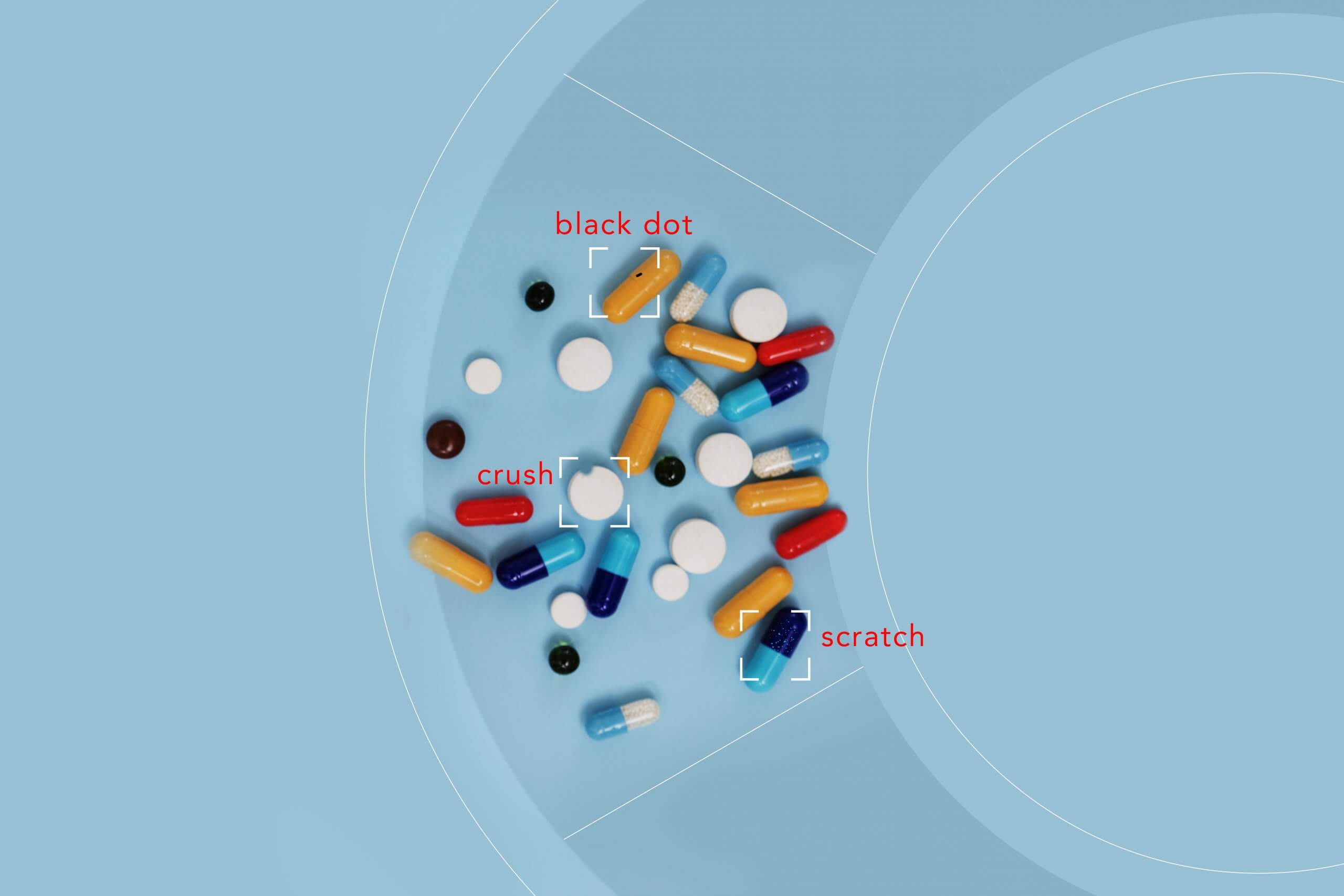

Defects Identification in Medicine

Using Computer Vision and Machine learning it is possible to spot problems of drug production at the manufacturing line. Using AI technologies for medicine the customer was able to reach the following goals:

- Identification of the medicine with defects (cracks, contamination, blotches, etc.) using CV and ML technologies;

- Reduction of the labour cost and labour interaction;

- Real-time detection of the flaws and instant notifications about the violations.

Technologies Used: Convolutional Neural Network for anomaly detection that will be developed and trained to satisfy the main goals of the task with the accuracy reaching more than 95%.

Tech Stack: TensorFlow, OpenCV, open-source and delivered to the customer site.

Artificial intelligence has incredible potential in the healthcare and pharma industries. The traditional manufacturing process seems risky today: it involves the possibility of human-made errors. More than that, it is not very cost-effective in terms of labor costs. Machine learning and computer vision for quality control are slowly becoming a reliable alternative to traditional operations.

PEOPLE ALSO READ

AI-Powered Permit Analyzer for Regulatory Compliance

Softengi developed an AI application that streamlines the review of complex permit documents.

Universal Data Lake Publishing Service for Large-Scale Data Publishing

Softengi successfully implemented a data lake publishing solution that addresses EHS vendor's critical data transfer challenges.

Mental Well-Being Clinic for Virryhealth

Softengi developed a virtual clinic with interactive and non-interactive activities where visitors could schedule therapy sessions with medical experts and visit a VR chat in the metaverse to interact with the amazing nature and animals of the African savanna.